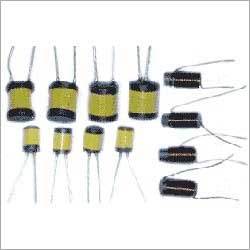

Drum Core Transformer

2.00 - 9.00 INR/Piece

Product Details:

- Load Loss <3W

- Coil Material High-grade enameled copper

- Voltage Booster Type Manual/Auto switch

- Rated Voltage 220V / 110V

- Cooling Type Air cooled

- Low Voltage 12V or 24V (Customizable)

- Operating Temperature -20C to +85C

- Click to View more

X

Drum Core Transformer Price And Quantity

- 1000 Piece

- 2.00 - 9.00 INR/Piece

Drum Core Transformer Product Specifications

- -20C to +85C

- 500 VA

- Drum core; winding enclosed

- 75mm x 45mm x 45mm

- Single Phase

- 98%

- 220V

- <3W

- 50-60

- Drum Core Transformer

- Approx. 450g

- Two (Primary & Secondary)

- High-grade enameled copper

- Manual/Auto switch

- AC

- 220V / 110V

- Copper wire with ferrite drum core

- Step down/up voltage applications in electronic circuits

- Up to 5kVA

- Air cooled

- 12V or 24V (Customizable)

Drum Core Transformer Trade Information

- 25000 Piece Per Day

- 1 Week

- Yes

- Free samples are available

- Carton packing available.

- All India

Product Description

We are one of the leading manufacturers and suppliers of wide fleet of Drum Core Transformer. These transformers are manufactured by our highly competent and dexterous professionals by making use of using optimum grade materials and most progressive technology. Available in different sizes and models for clients, our range of Drum Core Transformer is well known and appreciated for some its unique features such as high tensile strength,light weight, best performance, and durability.

Robust and Versatile Power Conversion

Designed with a drum core structure, this transformer delivers stable performance for both step-up and step-down AC voltage needs. Its enclosed winding ensures minimal magnetic loss, while air cooling keeps the device within a safe operating range of -20C to +85C. From powering audio equipment to high-efficiency battery chargers, its adaptability stands out.

Safety, Compliance, and Durability

Featuring high-grade enameled copper windings and ferrite drum core, the transformer meets IEC 60076-3 standards and offers a robust 1500V AC dielectric strength. Its Class B insulation and RoHS compliance guarantee safe, long-term use and environmental responsibility, making it a dependable choice for demanding industrial and commercial settings.

FAQs of Drum Core Transformer:

Q: How is the Drum Core Transformer installed in electronic systems?

A: The transformer supports both PCB mount and chassis mount options, allowing flexible integration into diverse electronic setups. Tinned copper leads facilitate secure soldering or wiring to your circuit board or enclosure.Q: What are the main applications for this Drum Core Transformer?

A: It is ideally used in adapters, battery chargers, audio devices, SMPS, and instrumentationanywhere step-up or step-down voltage conversion is essential in a single-phase AC environment.Q: When should I choose a Drum Core Transformer with this specification?

A: Opt for this model when your electronic project requires up to 500 VA capacity, robust insulation (Class B), high efficiency, and low noise performance, especially for safety or regulated equipment.Q: Where can this transformer be sourced, and is it export-ready?

A: Manufactured and supplied in India, the transformer is fully export-compliant, suitable for domestic and global distribution due to its adherence to international RoHS and IEC 60076-3 standards.Q: What is the process for customizing voltage outputs?

A: You can request customization for secondary voltages, typically offered in 12V or 24V variants, depending on your application requirements. The process involves specifying desired output during ordering.Q: How does the winding and insulation method benefit performance?

A: With layer-wound coils and insulated layers, the transformer minimizes energy loss and enhances safety, reducing risk of breakdown even under continuous load.Q: What are the advantages of using a manual or auto voltage booster type?

A: Manual or automatic switching lets you optimize voltage conversion based on real-time demand, improving application versatility and reducing energy losses during operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Electronics Transformer' category

We accept only bulk quantity orders.

Menu

Menu  Send Inquiry

Send Inquiry Send SMS

Send SMS