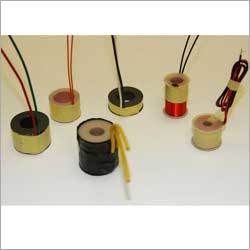

CFL Transformer Choke Coil

6.00 - 10.00 INR

Product Details:

- Low Voltage Down to 6V AC

- High Voltage Up to 240V AC

- Capacity Up to 0.05A-0.20A

- Dimension (L*W*H) 18 x 18 x 16 mm to 32 x 28 x 25 mm

- Operating Temperature -20C to +70C

- Rated Voltage 220V/240V AC

- Coil Material Enameled Copper Wire

- Click to View more

X

CFL Transformer Choke Coil Price And Quantity

- 6.00 - 10.00 INR

- 1000 Piece

CFL Transformer Choke Coil Product Specifications

- Low Voltage AC Output

- High

- 220V/240V AC

- Enameled Copper Wire

- -20C to +70C

- Double / Multiple

- 18 x 18 x 16 mm to 32 x 28 x 25 mm

- 6W - 85W CFL

- 50g to 180g (varies by model)

- Toroidal & EI types

- Single Phase

- 50-60

- Air Cooled

- Low

- Down to 6V AC

- Up to 0.05A-0.20A

- CFL Lighting Circuit

- Up to 240V AC

- Transformer Choke Coil

- Copper Core with Ferrite Core

CFL Transformer Choke Coil Trade Information

- Cash in Advance (CID)

- 500000 Piece Per Month

- 2 Days

- Yes

- Free samples are available

- Carton box packing available.

- All India

Product Description

Backed by a team of highly experienced and skilled manpower, we have emerged as a superior manufacturer and supplier of a wide assortment of CFL Transformer Choke Coil. To design and manufacture our range of coil, we have installed all the requisite machines and equipments at our sound manufacturing wing. Our range of CFL Transformer Choke Coil is well acknowledged for features such as economical, low maintenance, low power consumption, high efficiency.

Product details

| Power | 30W |

| Phase | Single Phase |

| Model Name/Number | ETD 44 |

| Input Voltage | 220V |

| Current | 3Amp |

| Frequency | 60Hz |

| Cooling Type | Dry Type |

| Usage/Application | Switching Power Supply |

Engineered for Modern Lighting

Our CFL Transformer Choke Coil is meticulously engineered to support energy-efficient lighting needs, including CFL lamps and electronic ballasts. With high precision winding and robust insulation (Class B or F), the design ensures safe, long-term functionality under varied ambient temperatures and humidity levels. Compatible with both toroidal and EI core structures, it fits a wide range of power ratings and lighting applications.

Reliable Performance & Longevity

Reliability is built into every choke coil, with features like high dielectric strength (1500V AC), superior varnish coating, and over 30,000 hours of life expectancy. The coil operates efficiently within -20C to +70C and at humidity levels up to 95% RH, maintaining performance in challenging environments. Adhering to IS/IEC/EN standards, it guarantees quality and safety for lighting solutions.

FAQs of CFL Transformer Choke Coil:

Q: How is the CFL Transformer Choke Coil installed in electronic circuits?

A: The coil is designed for easy installation on printed circuit boards (PCB) using solder pins or flexible wire leads, allowing secure mounting in compact lighting assemblies.Q: What applications can this choke coil be used for?

A: It is ideal for use in CFL lamps, electronic ballasts, and a variety of lighting fixtures where efficient voltage transformation and noise reduction are crucial.Q: When is it suitable to use Insulation Class B versus Class F?

A: Class B insulation is suitable for standard temperature conditions, while Class F provides enhanced heat resistance for environments with higher operating temperatures or stricter safety requirements.Q: Where is this product manufactured and supplied from?

A: This choke coil is manufactured, supplied, and exported from India, meeting international quality standards for lighting components.Q: What is the benefit of a layered precision winding and varnish coating?

A: Layered precision winding ensures consistent electrical characteristics and low loss, while the varnish coating provides robust electrical insulation and mechanical protection, extending the coils service life.Q: How does the product ensure safety and compliance?

A: It features high dielectric strength (1500V AC), RoHS compliance, and adheres to IS/IEC/EN design standards, guaranteeing both electrical safety and environmental responsibility.Q: What is the process for quality assurance during manufacturing?

A: Strict quality controls are implemented at every stage, including material selection (enameled copper wire, ferrite cores), precision winding, varnish coating, and final functional testing to ensure superior reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Choke Coil' category

We accept only bulk quantity orders.

Menu

Menu  Send Inquiry

Send Inquiry Send SMS

Send SMS