Drum Choke Coil

2.00 - 10.00 INR

Product Details:

- Low Voltage Suitable for low-voltage circuits

- Capacity Standard inductor values, 10 H to 500 H (model dependent)

- Coil Material Copper

- Rated Voltage 100V - 250V (as per model)

- High Voltage Not specifically rated for HV applications

- Dimension (L*W*H) Typically 10mm x 12mm x 16mm (varies by model)

- Operating Temperature -40C to +125C

- Click to View more

X

Drum Choke Coil Price And Quantity

- 1000 Piece

- 2.00 - 10.00 INR

Drum Choke Coil Product Specifications

- High

- Power supply filtering, RF suppression, noise filtering, electronic circuits

- Low, dependent on winding and core

- Copper

- Single coil (standard); customizations available

- Air cooled

- Ferrite core, Copper winding

- Standard inductor values, 10 H to 500 H (model dependent)

- Inductive filtering

- -40C to +125C

- Suitable for low-voltage circuits

- 100V - 250V (as per model)

- Up to 100 MHz (depending on model)

- Drum core with pre-wound copper wire

- Approx. 5-50 grams (depending on size and model)

- Not specifically rated for HV applications

- Single phase / Three phase (varies by application)

- Low to medium power electronic devices

- Typically 10mm x 12mm x 16mm (varies by model)

- Drum Choke Coil

Drum Choke Coil Trade Information

- Yes

- Free samples are available

- Carton box packing available.

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- All India

Product Description

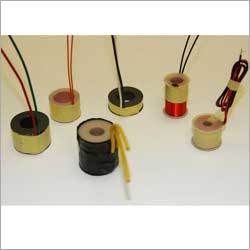

We are a certified manufacturer and supplier of wide ambit of Drum Choke Coil. Our offered coils are designed and manufactured with the assistance of high grade raw materials and highly progressive technology so as to ensure its flawlessness. Available in different sizes, models, these coils cater to various industry purposes and applications. Our range of Drum Choke Coil is well acknowledged for features such as optimum performance, longer service life and cost-effectiveness and the likes.

Product details

| Voltage | 220V |

| Size | 10mm (L) |

| Frequency | 50Hz |

| Material | Copper |

| Inductor Type | SMD |

| Usage/Application | Switching Power Supply |

| Current | 3Amp |

Precision and Robust Design

Featuring a drum core with a ferrite or EI material, our choke coils are meticulously wound with copper wire for consistent performance. The insulated varnish finish enhances durability, while options like PCB and panel mounting accommodate diverse installation requirements.

Wide-Ranging Industrial Applications

Engineered for power electronics, EMI suppression, energy meters, and electronic circuits, these drum chokes provide dependable inductive filtering up to 100 MHz (varies by model). Their rugged construction and versatile mounting options suit most industrial and commercial environments.

Standards Compliance & Environmental Protection

Manufactured in accordance with IS/IEC standards and RoHS compliant, these choke coils assure safety, reliability, and eco-friendly usage. Their Class B insulation or higher assures dependable performance across a wide temperature spectrum.

FAQs of Drum Choke Coil:

Q: How do I select the appropriate Drum Choke Coil for my application?

A: Choose the coil based on your circuits inductance (100 H 20 mH), resistance requirements (under 20 Ohms), mounting type (PCB or panel) and terminal style (solder lug or lead wires). Also, ensure it meets your voltage and current needs as well as environmental conditions.Q: What are the main benefits of using a Drum Choke Coil with a ferrite core?

A: Ferrite cores offer high efficiency, excellent frequency handling (up to 100 MHz), and strong EMI suppression, making them ideal for noise filtering, power supply applications, and high-frequency circuits.Q: When is a Drum Choke Coil typically used in electronic circuits?

A: These coils are commonly used during the design or upgrade of power supplies, energy meters, and circuits needing RF suppression, EMI reduction, or stable inductive filtering.Q: Where can Drum Choke Coils be mounted within equipment?

A: They can be mounted directly onto printed circuit boards (PCB mount) or fixed to panels (panel mount), offering flexibility for assembly across different device types and enclosures.Q: What manufacturing process is used for these Drum Choke Coils?

A: A precision-wound technique ensures accurate coil parameters, with copper windings around a ferrite or EI core. This guarantees consistency, low load loss, and optimal performance.Q: How does this coil handle environmental stress such as shock and humidity?

A: The coils are designed to withstand shocks up to 10g and can tolerate up to 90% relative humidity. They operate reliably within a temperature range of -40C to +125C, making them robust for varied conditions.Q: What standards and certifications do these choke coils meet?

A: They are manufactured in compliance with IS/IEC standards and are RoHS compliant, ensuring adherence to safety, performance, and environmental regulations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Choke Coil' category

We accept only bulk quantity orders.

Menu

Menu  Send Inquiry

Send Inquiry Send SMS

Send SMS